Machinery Health

Management Suite

Using digitalization technology to prevent downtime losses and extend machine lifespans

In order to avoid unplanned downtime of the sold equipment, and improve the after-sales capacity of equipment manufacturers and customer relations, through digital technology, equipment networking technology, including real time repair/maintenance, KPIs, health prediction and other functions, real-time attention to equipment health of this package.

Connect the triangle relationship of equipment manufacturer, customer and machines, and reduce maintenance costs, improve equipment security, and availability, equipment manufacturers can have more confident to master the global equipment operations and sales.

Strength and Value Proposition

Accelerate Your Digital Transformation with

Machinery Health Management Suite

Machine Maker

- Real-time data is instantly and securely streamed through the Advantech cloud platform to one centralized location.

- Instant analytic and insight visualization helps improve your ability to make decisions based on real data.

- Access and manage machines, no matter where in the world they are.

Channel / Distributor

- Enhance sales strategies through seeing real – time machine status, and solving pain points.

- Prepare just enough spare parts by reviewing the usage of machines at the customers factory.

Factory Site / End User

- No worry about lacking machine spare parts, unplanned machine downtime, and quick recovery through the strategy of using a combination of preventive and predictive maintenance.

- Real-time monitoring of the machine, in advance to detect abnormal condition of equipment, reduce the chance of equipment downtime to affect production.

Digital Transformation Application Story

Smart machinery for digitizing shoe-manufacturing machines

“Through this service, the shoe machine manufacturer was able to increase assembly speed, capture equipment data, view systematic and visualized data presentation, perform preventative maintenance and remotely manage all aspects of production across plants and lines. Both parties will continue cooperation in the future to expand the smart functionalities of production.”

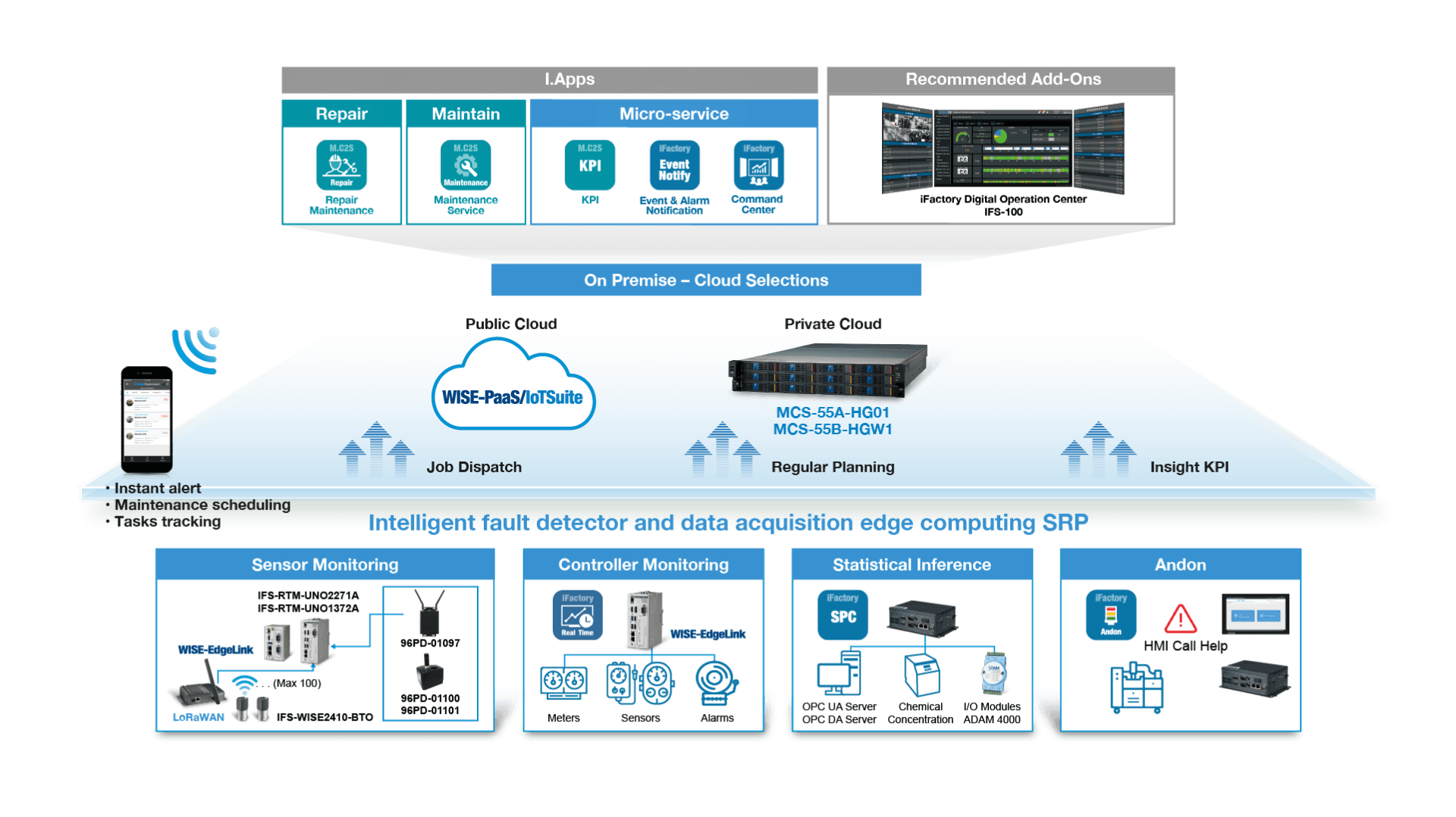

System Structure of Machinery Health Management Suite

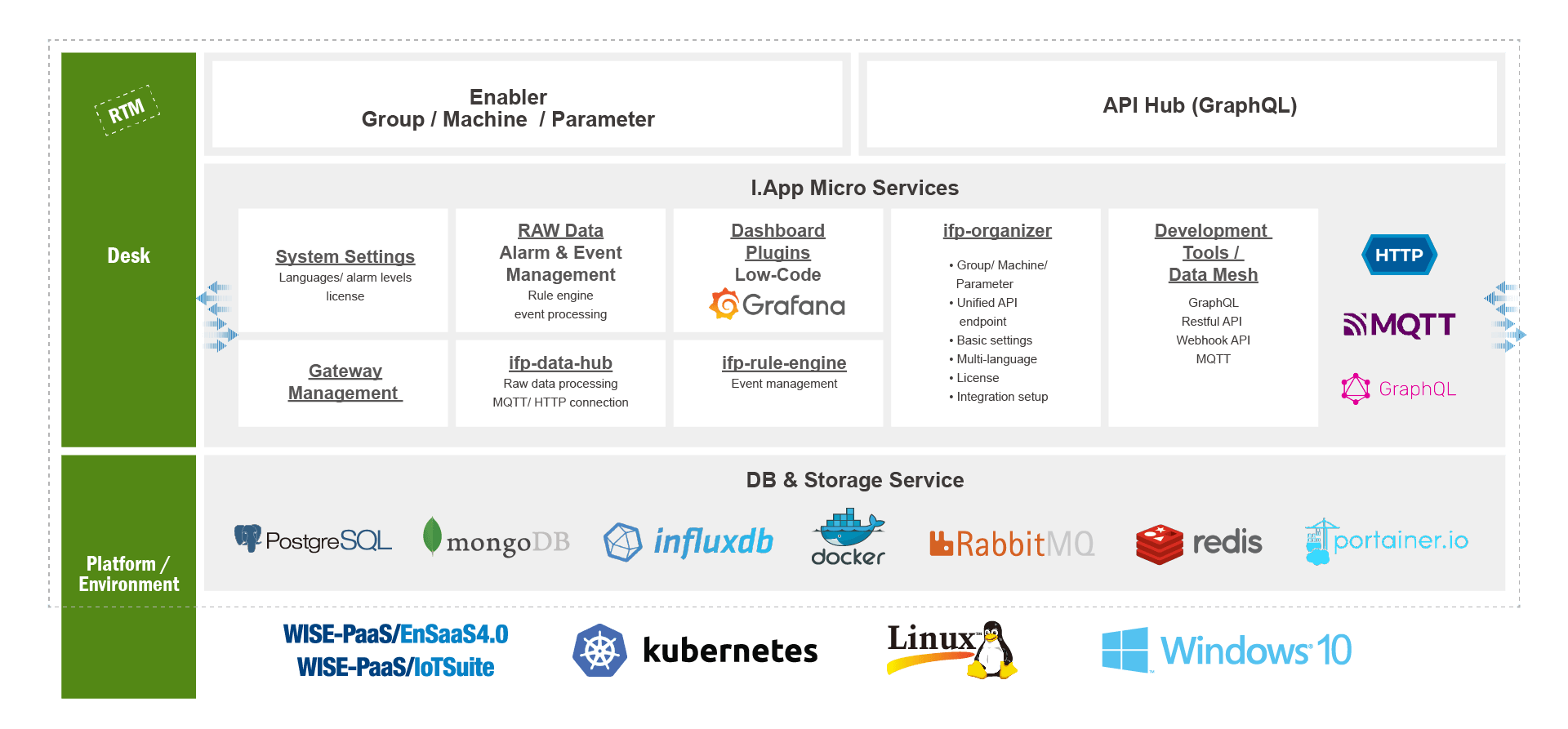

Machine C2S/DAS Software Architecture

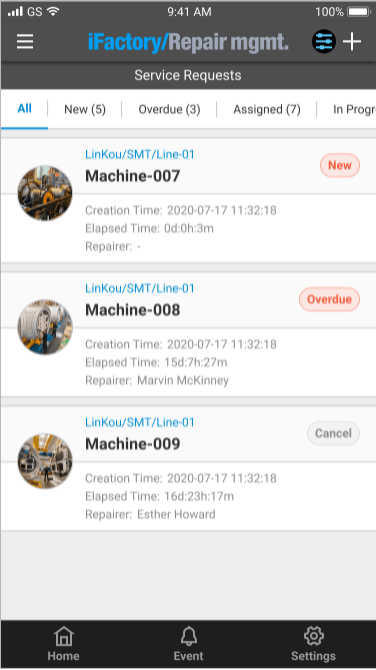

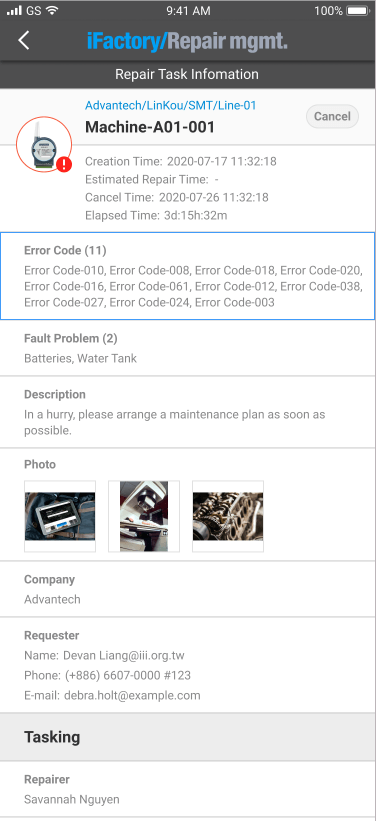

Ready-to-Use I.Apps – Data Visualization Dashboards

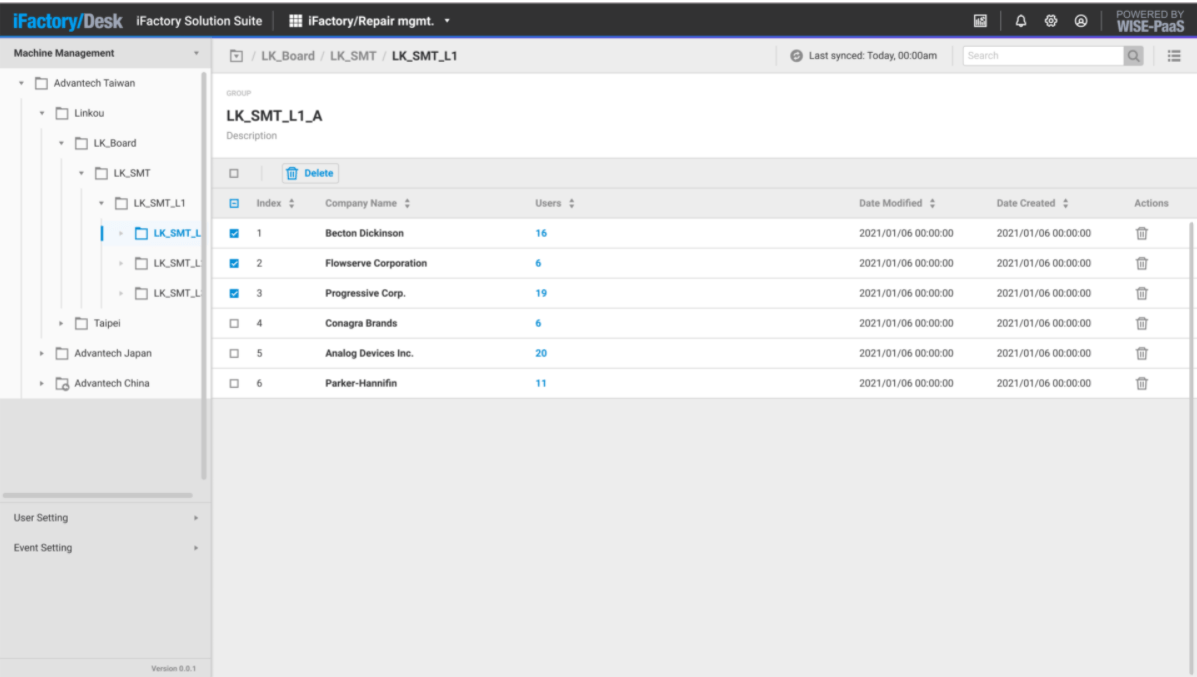

- Electronic process management to improve management flexibility

- Collect request information and trigger request fulfillment workflow

- Use Mobile services to remote controlling

- Customize web forms to suit your needs

- Logging requests to keep your customers updated

- Set up SOP for proper procedure and techniques

- Electronic process management to improve management flexibility

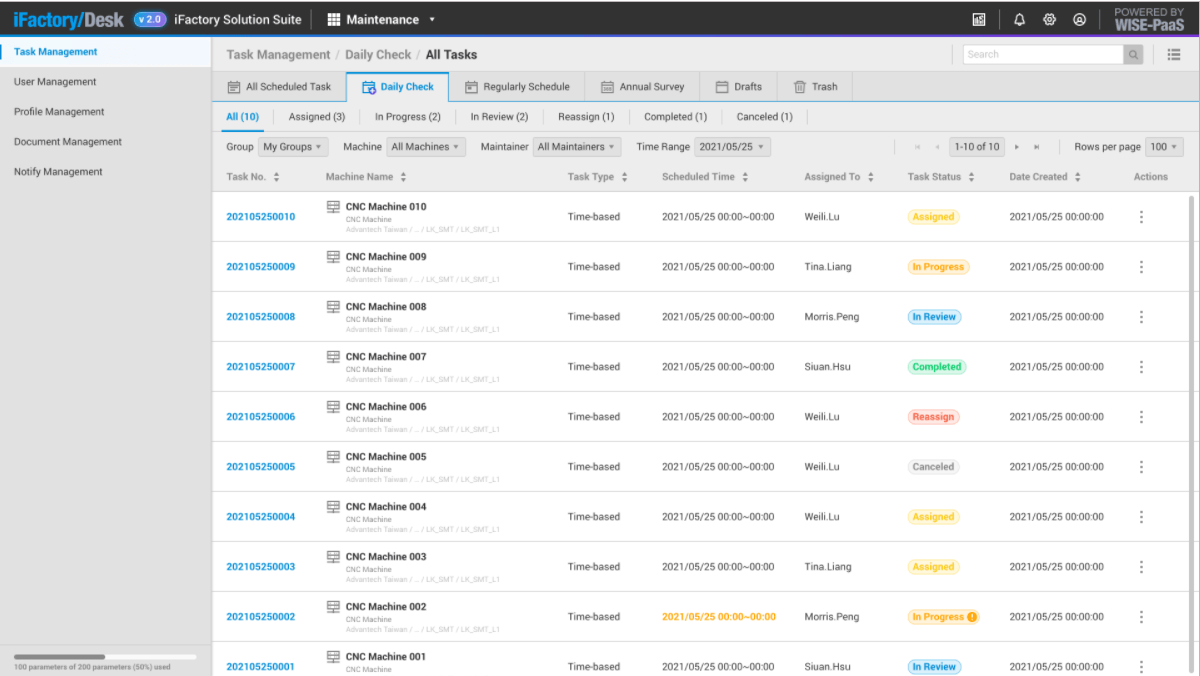

- Usage Based and Time based maintenance function

- Connect with materials management function, replace worn components before the fail

- Set up SOP for proper procedure and techniques

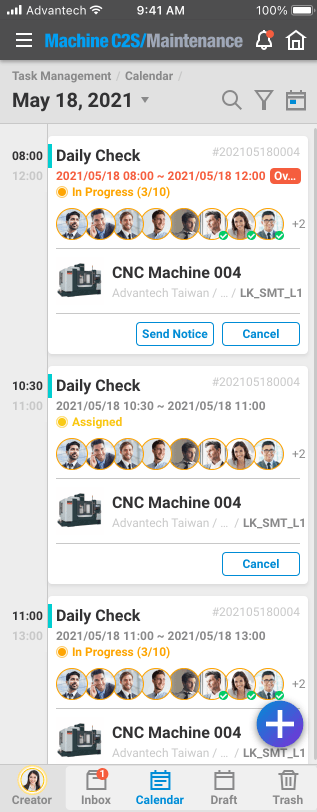

- The calendar function provides complete monitoring of all work order times and conditions

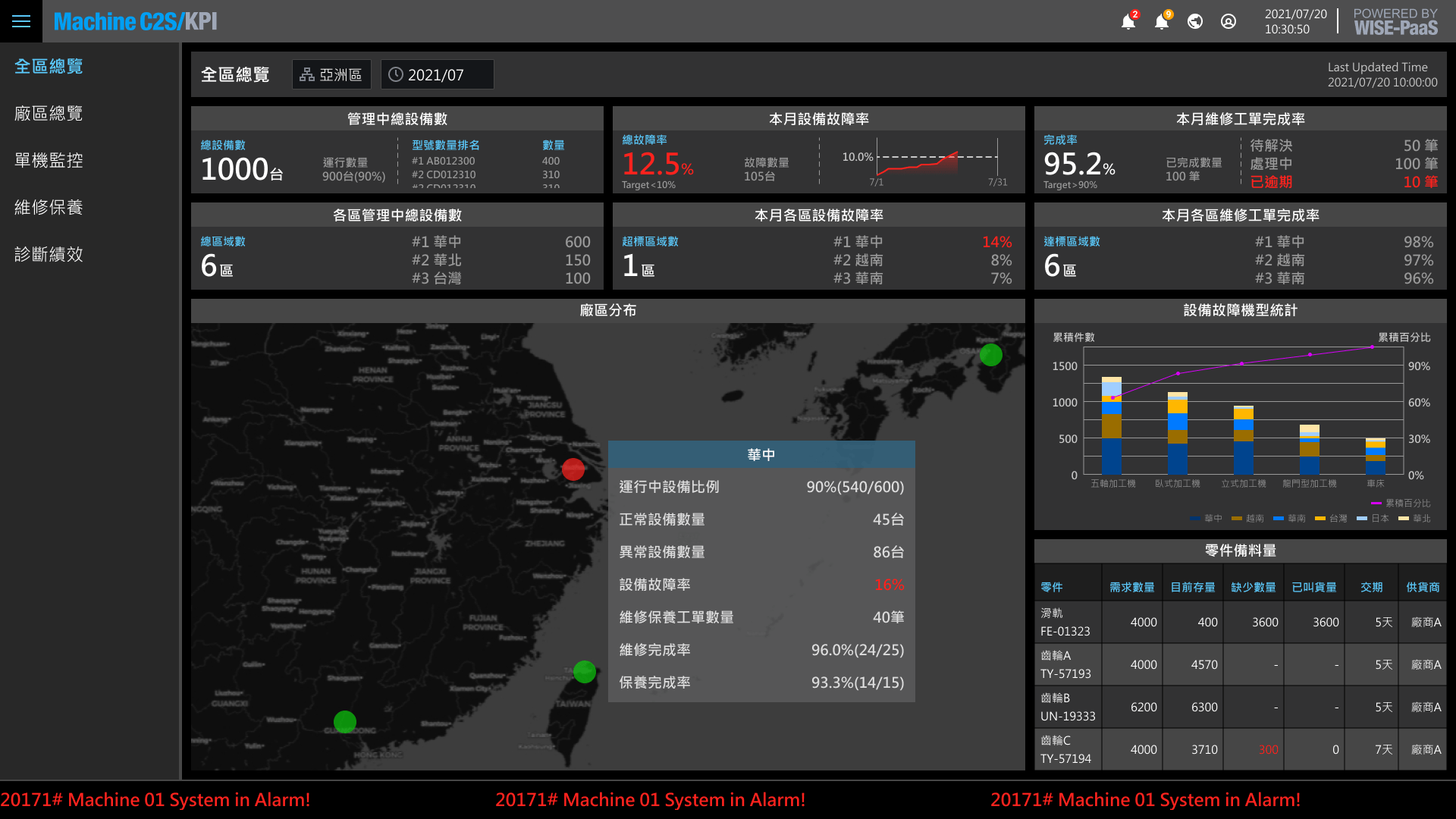

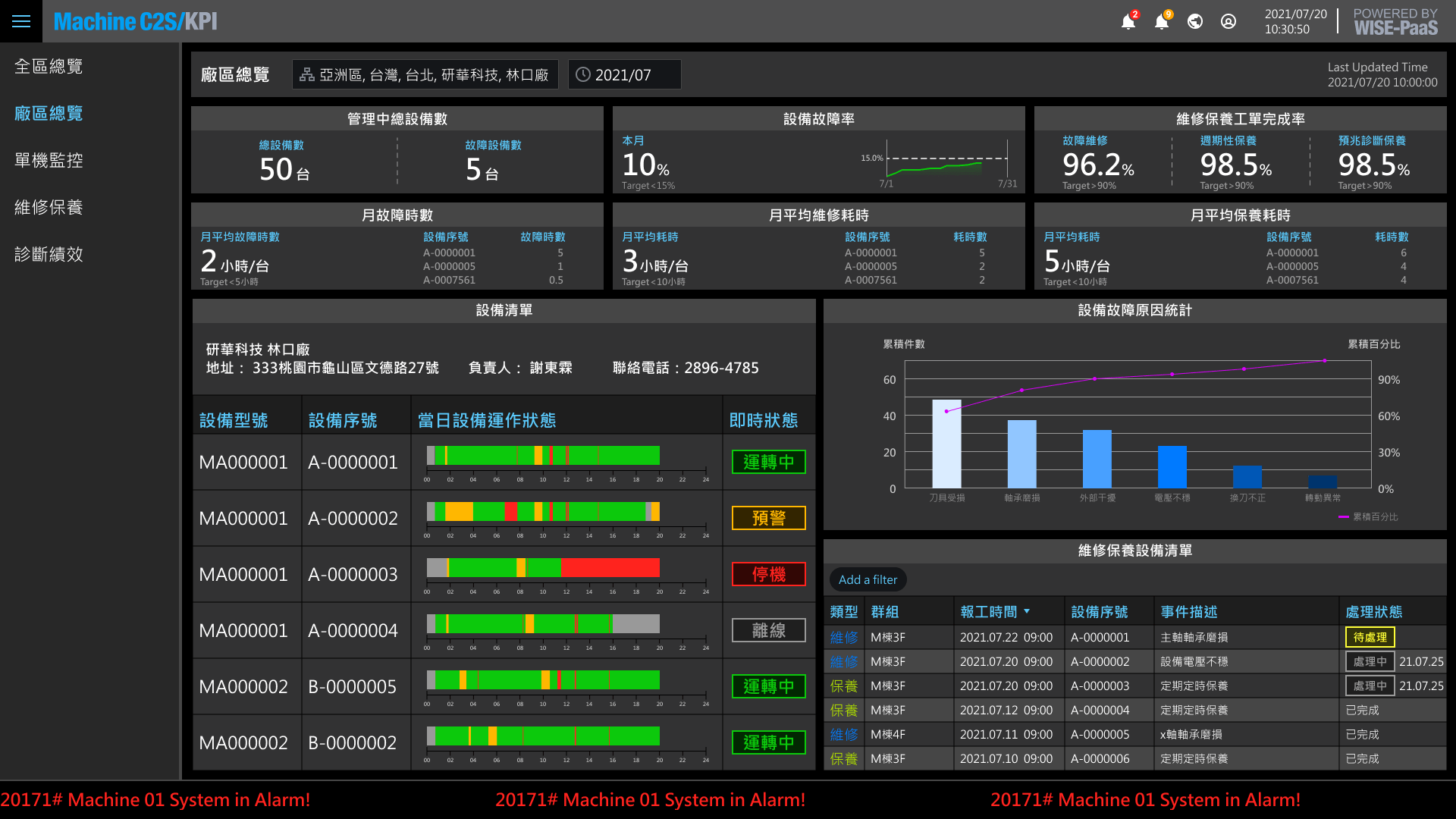

- Provides managers with real-time access to the global sales network through the world map of the equipment connection status and provide important comprehensive indicators information.

- Enable managers to quickly identify unusual sites and make relevant decisions. In addition, KPI indicator values provide the most immediate equipment maintenance status for performance tracking.

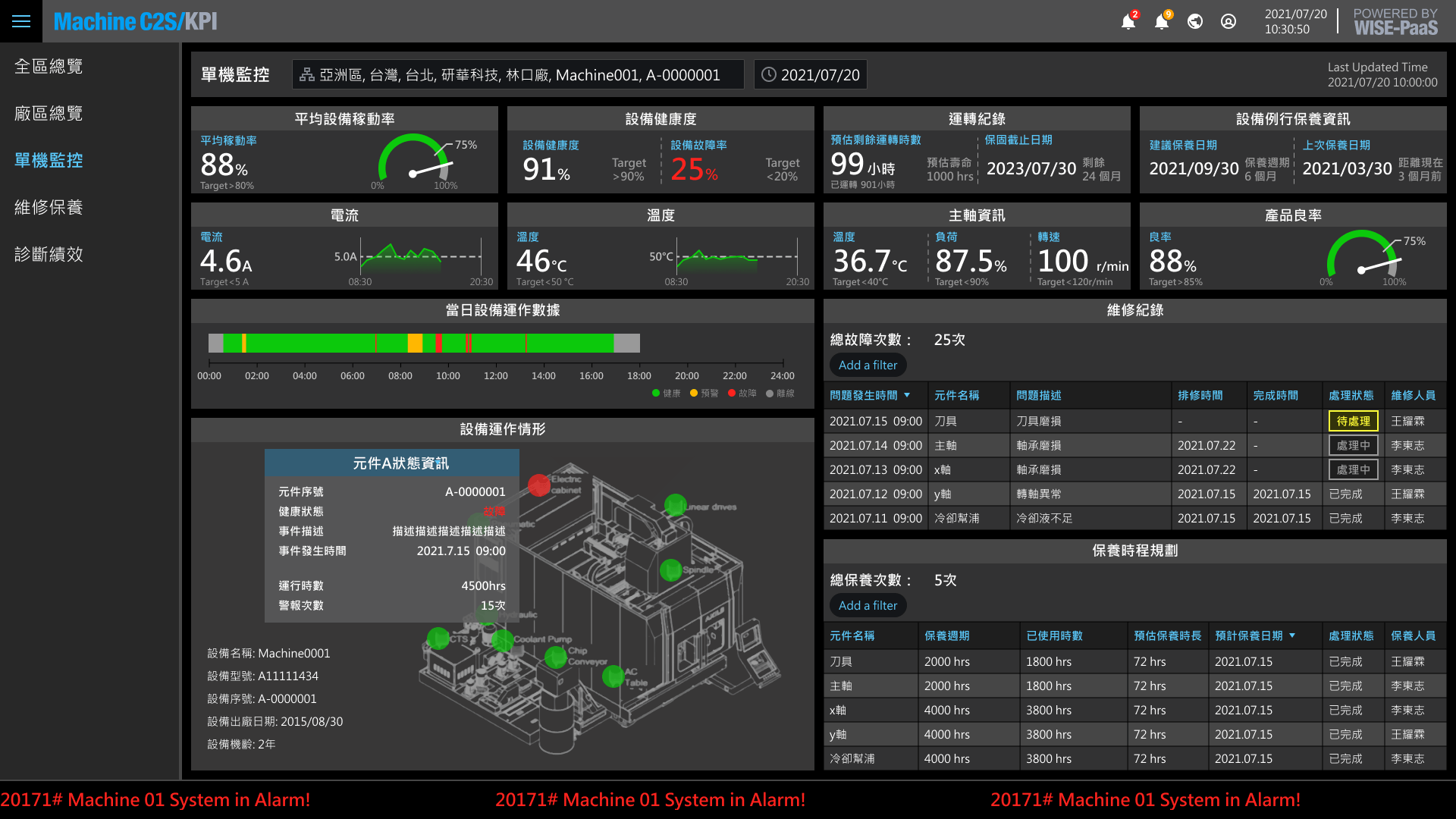

- View data on key metrics for a single unit, including real-time data on key components, maintenance status and recommendations, and more.

- Provide managers with a list of regular maintenance schedule times and status, as well as tracking maintenance records

- Provide critical equipment indicator forecast, through the sensor collected data through data pre-processing, data cleaning and data mining, to determine its decision-making and maintenance implementation recommendations, early detection of symptoms of problems to advance maintenance or replacement of components to avoid unplanned downtime

Use I.App Building Blocks to Construct Your Own IoT Smart Manufacturing Solutions

Reach out now!

We're here to help you get started.