Industrial Equipment Manufacturing > Food and Beverage Manufacturing

“ Food Safety, Margin and Consumer ”

Keywords for Food and Beverage Manufacturing

Pre-Process

The pre-process phase mainly covers data collection, control and monitoring of the cleaning, cutting, classification processes by the digital system.

System Requirements:

- Time/Speed/Temperature/Pressure/PH value control and monitoring.

- Waterproof , splash-proof , anti-corrosion

- Variable frequency system to manage machine speeds, cycle times, and schedule rest times

- Output management

- Emergency stop function

Solution Highlights

Advantech provides solutions for centralized or dispersed deployments in F&B factories. Our solutions support mainstream protocols and multiple I/O. Our IPC and gateway have IP-69K rated protection. IP69K rating provides protection against ingress of dust and high temperature, high pressure water – making products with this certification ideal for use in conditions where equipment must be carefully sanitized like in F&B factories.

SPC-515

15" XGA Stainless Steel Multi-Touch Panel PC

- All-around IP69K protection

- Food-grade 304L stainless steel chassis

- Intel® Skylake Core™ i3-6100U 2.3 GHz processor (Dual-Core)

UNO-430-E1A

All-Around IP69K/IP68 Waterproof Edge Intelligence Gateway

- Intel® Atom E3950 Quad-core processor with 8G DDR3L memory

- Robust design for -40~70°C operating temperature, IP69K and IP68-rated protection.

- Enclosure with front door and cable gland design ensures easy installation and maintenance to serve as a standalone data acquisition gateway

AMAX-658

Modular Controller

- CODESYS Control SL ready for IEC-61131 language, suitable for material handling, conveyor systems and sorting process market

- SoftMotion & CNC Robotic easy connect with Servo Driver/Step Drive for complete EtherCAT solutions.

- Supports various IO and is flexible connect to Cloud or IT system by OPC UA, MQTT, ODBC(Database) for OT & IT Integration

Processing & Packaging

A key function in food processing and packing is motion control, which highly relies on axis execution, mobility, and control to achieve precise movement and positioning to accurately accomplish a variety of consecutive movements such as spin, roll, and tilt.

System Requirements:

- 3-axis motion control

- Speed control

- Variable frequency function

- Safety ON/OFF

- Procedure management

Solution Highlights

Advantech provides F&B solutions for high quality food-grade manufacturing. Solutions include different Intel processor options to suit different scales of manufacturing. It also supports common motion control systems and protocols, is compact and modular in design, and offers easy maintenance.

SPC-821

21.5" Full HD Standalone Multi-Touch Panel Computer

- All-around IP65 protection with integrated push buttons

- Intel® Skylake Core™ i3-6100U 2.3 GHz processor (Dual-Core)

- Silicone-free design avoids silicone contamination

UNO-137

Modular DIN-rail Control PC

- Intel® Atom® E3940 processor for economic design

- Supports wide temp. operation (-40 ~ 70°C) and modular design for optional 1 x iDoor expansion to support various industrial fieldbus applications

- 2 x LAN, 2 x COM, 4 x USB, 2 x DP for convenient local device connection and HMI usage

UNO-430-E1A

All-Around IP69K/IP68 Waterproof Edge Intelligence Gateway

- Intel® Atom E3950 Quad-core processor with 8G DDR3L memory

- Robust design for -40~70°C operating temperature, IP69K and IP68-rated protection.

- Enclosure with front door and cable gland design ensures easy installation and maintenance to serve as a standalone data acquisition gateway

AMAX-637

Cabinet Controller

- CODESYS Control SL ready for IEC-61131 language, suitable for material handling, conveyor systems and sorting process market

- SoftMotion & CNC Robotic easy connect with Servo Driver/Step Drive for complete EtherCAT solutions

- Flexible connect to Cloud or IT system by OPC UA, MQTT, ODBC (Database) for OT & IT Integration

AMAX-658

Modular Controller

- CODESYS Control SL ready for IEC-61131 language, suitable for material handling, conveyor systems and sorting process market

- SoftMotion & CNC Robotic easy connect with Servo Driver/Step Drive for complete EtherCAT solutions

- Supports various IO and is flexible connect to Cloud or IT system by OPC UA, MQTT, ODBC (Database) for OT & IT Integration

Quality Control

When food quality inspection relies on manual (or human visual recognition) manufactures suffer inefficiencies. Legacy automation systems might have reached the limit of inspection efficiency. But now AI inspection is being introduced into the production line, so inspection accuracy, speed and efficiency all increase.

System Requirements:

- Visual inspection

- Data visualization

- High-res graphic capture, processing, and recognition

- AI computing & deep learning

Solution Highlights

Advantech provides a comprehensive AI inspection solution, which includes intelligent vision inspection, monitoring, deep learning and training, which not only improves accuracy and speed, but with AI training, the system can optimize , remodel, and upgrade inspection models in production.

MIC-710AIX

Fanless Compact AI Inference System based on NVIDIA® Jetson Xavier™ NX

- Compact fanless design

- NVIDIA® Jetson™ Xavier NX embedded

- 2 x embedded LAN port

- Linux OS with board support package (BSP)

- Supports deep learning trained models

- Wide operating temperature range

- Support 24/7 secure remote monitoring, control, and OTA deployment empowered by Allxon

TPC-B610

Fanless Desktop Performance Touch Panel PC with Intel® 10th Gen. Core™ i CPU Socket

- 6 x Panel Modules (IP66) ranging from 15" to 23.8" in selection

- Dual Channel Memory slots (DDR4) support up to 64GB in total

- Comprehensive I/Os, including 6 x USB, 2 x COM, 2 x RJ45...etc

- Supports multiple storage and expansion via 1 x PCIe x16, 1 x mPCIe, 2 x M.2 (NVMe, SATA, 5G)

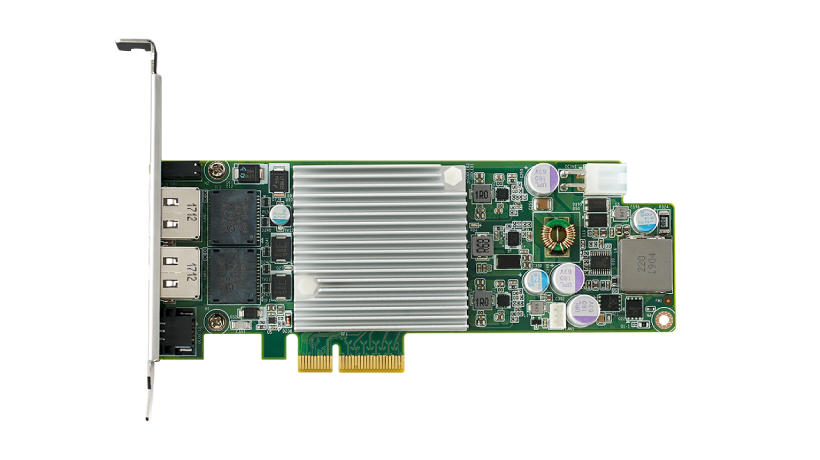

PCIE-1674

4-Port PCI Express GigE Vision Frame Grabber

- Intel® server-grade GbE Mac Controller

- PCI Express® x4 compliant

- PoE power from PCIe slot(Total Max. 18W)

- Powered Device (PD) auto detection and classification

- Supports IEEE 802.3u Auto-Negotiation

- Supports Jumbo frame (9,500 byte) and link aggregation

- Supports IEEE-1588 and IEEE-802.1 AS

- Per port power on/off control (PCIE-1674V)

Food Traceability

Food production requires total food history management that can record data and track workflows, which improves food quality and safety, and allows predictive maintenance.

System Requirements:

- Data visualization

- High hardware and software compatibility and scalability

- Remote management

Solution Highlights

Advantech Food Traceability solution includes high-end IPCs, which are equipped with advanced Intel processers and high-speed networking equipment. They meet the requirements for food data recording and storage on production lines and in control centers. They offer the advantages of visualization, high reliability, high security, high scalability, and easy management.

HPC-8208 + ASMB-816T2

2U Rackmount Server

- Ensures production continuity and data integrity with fault-tolerance software

- Enjoy 99.999% industrial application uptime

- Supports built-in visualization and 24/7 operation with constant uptime for industrial applications

ACP-4340 + AIMB-787

Intelligent 4U Rackmount IPC

- Intel® 10th generation Core™ i9/i7/i5/i3/Pentium®/Celeron® processor with Q470E chipset

- Supports up to 128GB of duel-channel (non-ECC) DDR 2400/2666/2933 MHz memory

- Accommodates 4 hot-swap drive trays

TPC-317-R873A

17" SXGA Panel PC

- 5G Supported

- Equipped with TPM 2.0 Hardware Security

- Built-in NVMe storage interface, and dual channel RAM support up to 64G DDR4 , suitable for high speed application

Smart Management of Devices with Advantech Edge Software

DeviceOn/BI

Device Management and Business Integration Platform

- Hierarchical organization twin object management

- Dashboard wizard

- Open API plugin for data exchange

- Easy interface with low learning curve

- Instant and dynamic domain logic scenario co

- Available in cloud or on-premise versions

WebAccess/SCADA

Industrial IoT Application Software Platform

- Enables 100% web-based remote engineering, monitoring, and control.

- Supports standard protocols including Modbus, OPC UA, OPC DA, Ethernet/IP, DNP3, SNMP and BACnet.

- Driver support for major PLCs, PACs, I/O modules, CNCs, network switches, and computer platforms.

WISE-EdgeLink

Powerful Edge-to-Could Middleware for Intelligent Gateway Solutions

- Lightweight gateway software for uploading data from the edge to the cloud.

- Supports communication with 200+ PLCs and IO modules equipment data integrated into middleware with secure data conversion

- Data publishing capabilities via OPC-UA, Modbus, DNP3, BECnet, MQTT, and LwM2M.

- Data backups to database and FTP server.

Recommended Product Offerings

► AI Platform

HPC-7000+ASMB-816

PCIe Gen4 Tower Server

MIC-730AI

Fanelss Compact AI Inference System based on NVIDIA Jetson® Xaviera

► Industrial PC

UNO-348

High Performance Embedded

Control PC

UNO-137

DIN-Rail Automation

Controller

► Vision & Motion Controller Solution

AIIS-3400/AIIS-3410

Compact Vision System

MIC-770 V2 + MIC-75G20

Fan-less system with

GPU expansion iModule

PCIE-1182

2-port PCI Express 10 GigE

Vision Frame Grabber

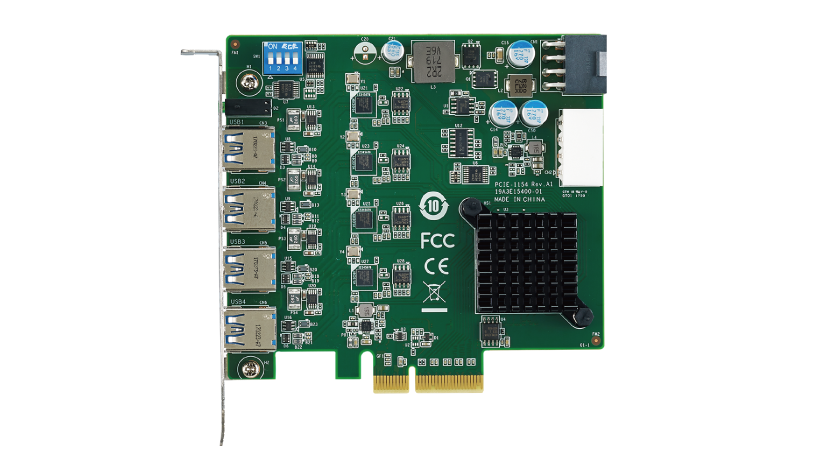

PCIE-1154

4-port PCI Express USB

Vision Frame Grabber

► Visualization

SPC-221

21.5" Full HD Stationary Multi-Touch Panel Computer

FPM-815S

15" XGA

Industrial Monitor

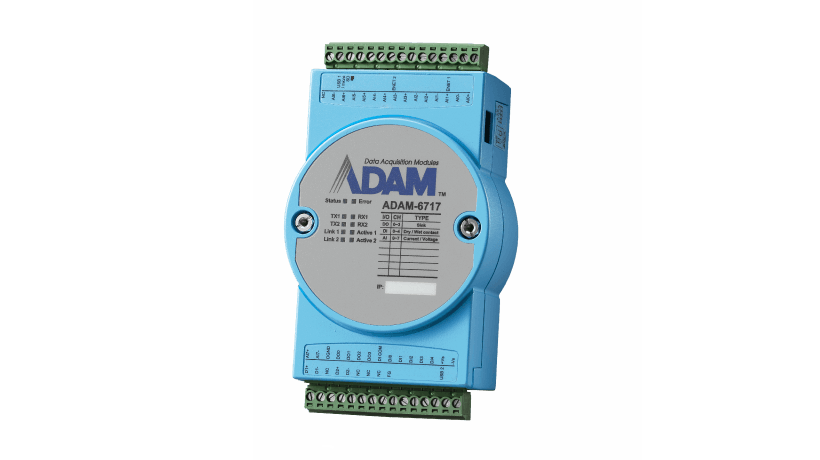

► IO Modules & Gateway

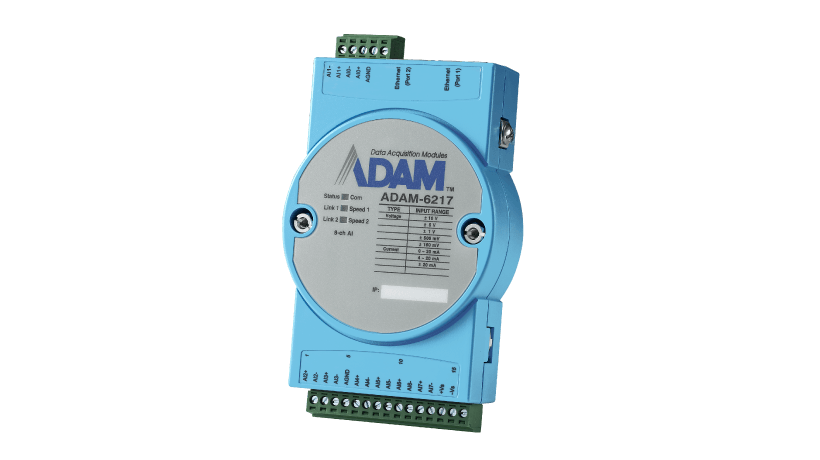

ADAM-6200

Ethernet I/O Modules

with Daisy Chain

ESRP-PCS-ADAM6700 Series

All-in-One Intelligent

I/O Gateway

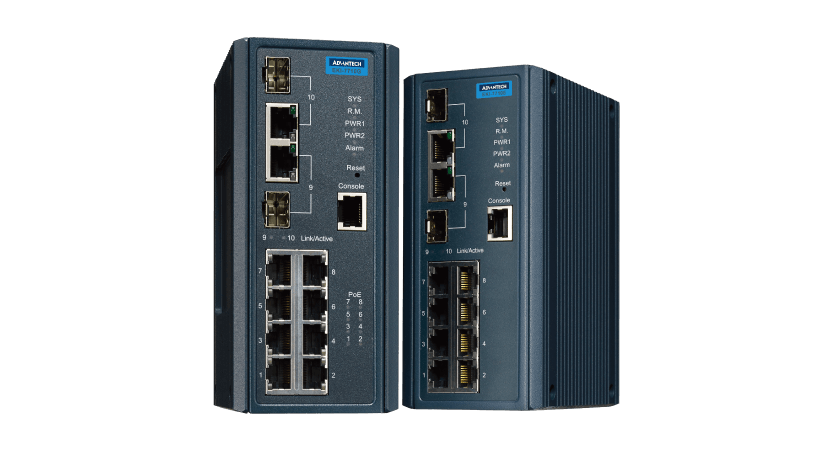

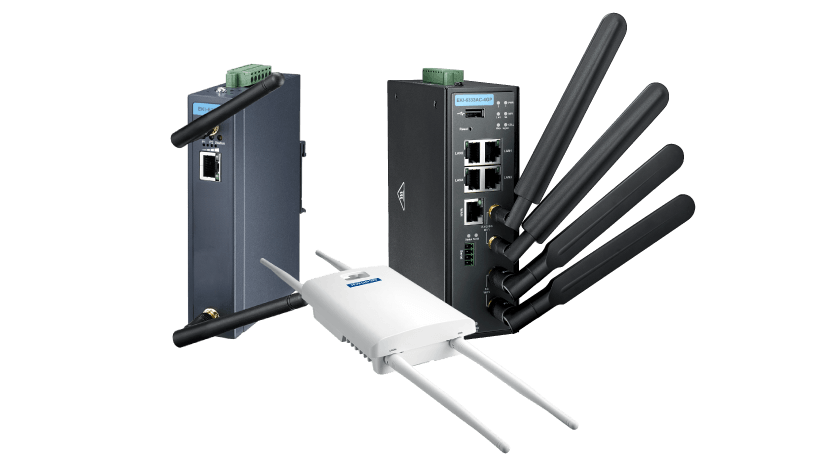

► Connectivity

IMC-390 Series

Industrial PoE/PoE+ Fiber-to-Ethernet Media Converter

EKI-7700 Series

Industrial Meneged

Ethernet Switch

EKI-1511 Series

1-Port RS-232 Serial Device Server with Wide Operating Temperature

EKI-1220 Series

Induastrial Modbus and

Fiedbus gateway