iFactory > iFactory EAM Solution

Equipment Automation Management Solution

Maximize Machine Reliability and Performance

Data-Driven Asset Management

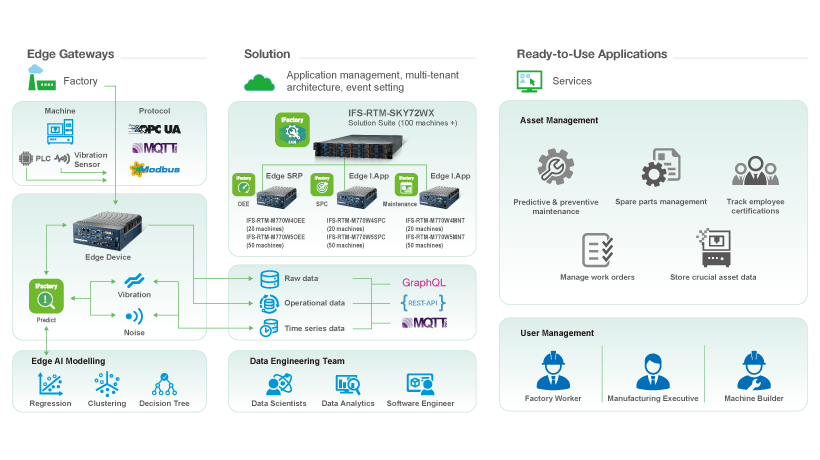

In compliance with ISO 55000 asset management standards, machine data is analyzed for insights to improve decision-making, increase efficiency, facilitate preventive maintenance, and maximize investment in physical assets.

Real-Time Analytics

The multi-tenant platform leverages numerous I.Apps for AI-based status monitoring and real-time analytics to obtain actionable insights and KPIs, such as machine OEE, to enable smarter decision making based on real data.

In the industrial sector, factory assets represent a large proportion of an enterprise’s key resources. Therefore, ensuring reliable machine operation is essential for producing quality products at a consistent pace. Advantech’s iFactory EAM (Equipment Automation Management) solution combines various software, systems, and services that are designed to maximize the lifecycle and performance of factory assets. In addition to providing machine KPIs, iFactory EAM solution supports order management, asset maintenance, planning and scheduling, real-time alert notifications, mobile management, and quality monitoring. Moreover, with the integration of modular iFactory industrial applications (I.Apps), iFactory EAM solution can be used to optimize operations, increase asset utilization, and maximize productivity.

Application Scenarios

Real-Time Monitoring of Machine Production

- Track production operations and bottlenecks for continuous improvement

- Calculate OEE based on production availability, performance, and quality

Predictive and Preventive Maintenance

- Reduce unplanned machine downtime and maintenance/repair costs

- Increase operational efficiency and extend the machine lifespan

Quality Control and Assurance

- Minimize rejection rates and improve product quality with SPC control charts

- Identify product defects/abnormalities and alert operations with push notifications

Equipment Automation Management Solution

- Machine performance transparency

- Digital repairs & maintenance

- Failure analysis

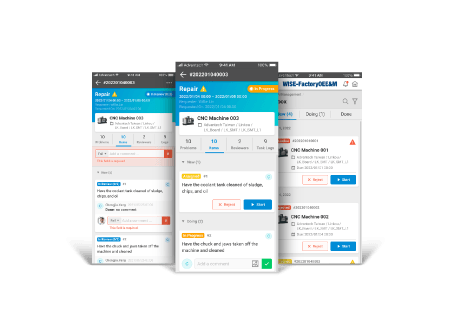

Equipment Maintenance Service – Mobile Management

The application interface can be accessed from a mobile device for a real-time overview of upcoming, ongoing, and completed work orders.

Equipment Maintenance Service – Customizable Dashboards

Customizable dashboards allow collected data to be visualized and easily understood at a glance.

Statistical Process Control (SPC)

SPC uses statistical methods for monitoring and controlling production line processes to ensure products meet precise specifications.

Success Story

Get to Know More about "iFactory EAM Solution"

Solution Ready Package Offerings

Overall Equipment Effectiveness (OEE)

IFS-RTM-M770W4OEE

Supports 20 machines, MIC-770 V2 system with Intel® i5 CPU, 16 GB, 128 GB SSD + 512 GB HDD, Win 10 OS, and preinstalled RTM/OEE I.App

Overall Equipment Effectiveness (OEE)

IFS-RTM-M770W5OEE

Supports 50 machines, MIC-770 V2 system with Intel® i7 CPU, 32 GB, 128 GB SSD + 1 T HDD, Win 10 OS, and preinstalled RTM/OEE I.App

Statistical Process Control (SPC)

IFS-RTM-M770W4SPC

Supports 20 machines, MIC-770 V2 system with Intel® i5 CPU, 16 GB, 128 GB SSD + 512 GB HDD, Win 10 OS, and preinstalled RTM/SPC I.App

Statistical Process Control (SPC)

IFS-RTM-M770W5SPC

Supports 50 machines, MIC-770 V2 system with Intel® i7 CPU, 32 GB, 128 GB SSD + 1 T HDD, Win 10 OS, and preinstalled RTM/SPC I.App

Equipment Maintenance Service

IFS-RTM-M770W4MNT

Supports 20 machines, MIC-770 V2 system with Intel® i5 CPU, 16 GB, 128 GB SSD + 512 GB HDD, Win 10 OS, and preinstalled RTM/Maintenance I.App

Equipment Maintenance Service

IFS-RTM-M770W5MNT

Supports 50 machines, MIC-770 V2 system with Intel® i7 CPU, 32 GB, 128 GB SSD + 1 T GB HDD, Win 10 OS, and preinstalled RTM/Maintenance I.App

Additional Recommended Purchase

Remote Terminal Unit

(RTU)

WISE-PaaS/EdgeLink, 8 x DI, 4 x DO, 8 x AI, 4-slot I/O expansion

Panel PCs

11.6"/15.6" All-in-one panel PC with Rockchip 3399 processor and Android 10 OS

Reach out now!

We're here to help you get started.