Take charge of your factory

Unleash Production Capability of

Lithium Ion Battery Giga-Factories

Advanced vision and control technologies drive new inroads into lithium ion battery manufacturers

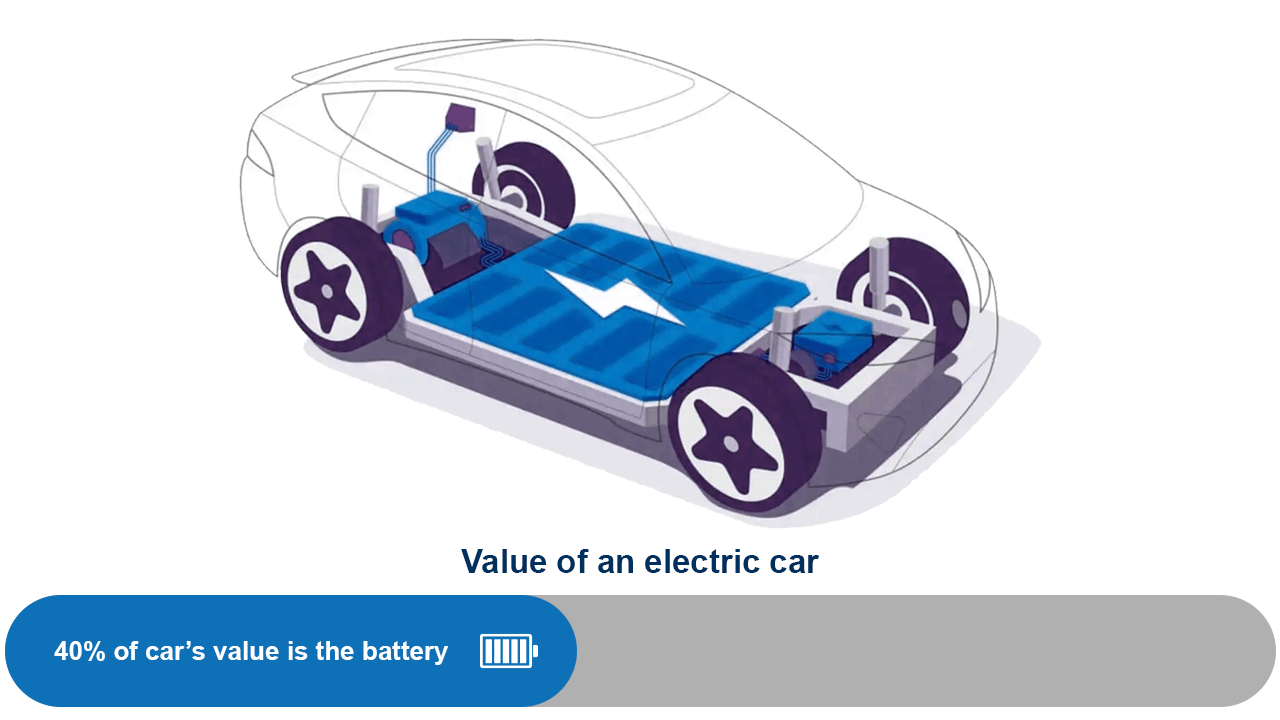

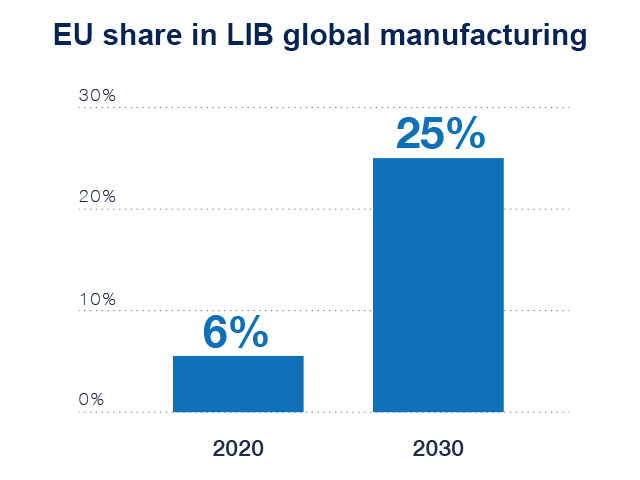

Electric vehicles and static storage systems are the main factors driving exponential demand increases in the European lithium-ion battery (LIB) market in the coming years. LIB forms the foundation upon which the future of the renewable energy and automotive industries will depend, and supply chain localization is therefore of critical strategic importance to European nations.

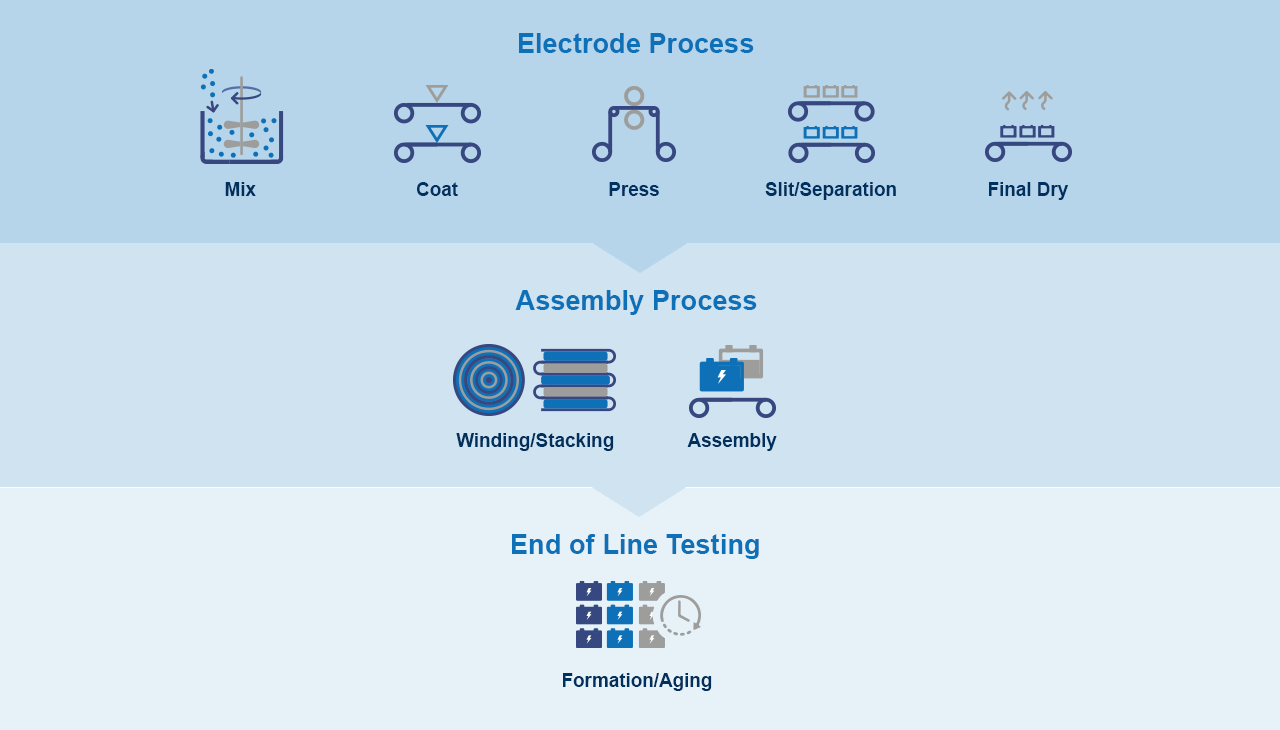

Lithium Ion Battery Cell Production Process

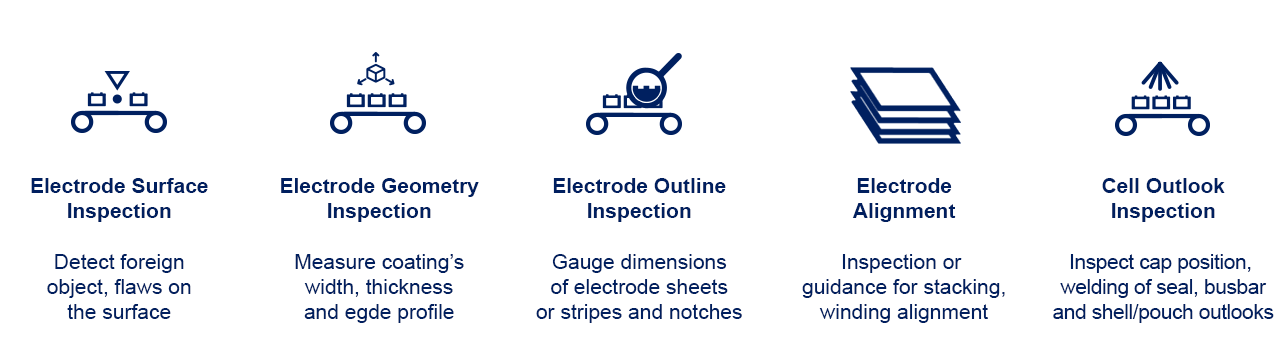

Electrode/cell quality and manufacturing equipment parameters are under strict monitoring and control using cutting edge machine vision and real-time control technologies to assure battery lifetime, performance and safety.

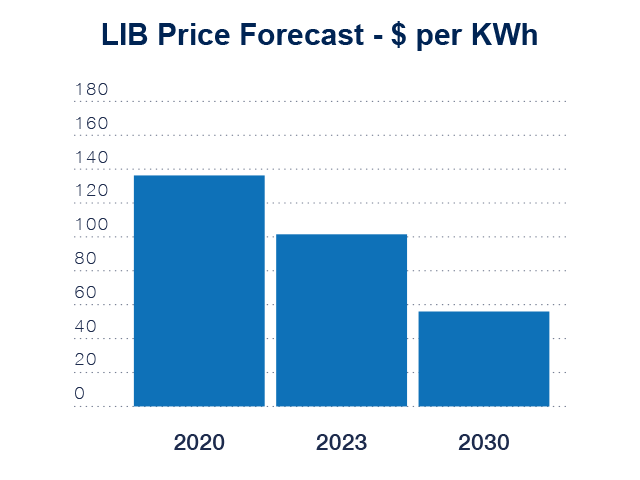

20% ~ 35% battery production cost reduction (excluding materials) can be achieved by operational excellence to keep Giga-factories profitable as LIB market prices decrease.

Advantech offers advanced solutions to keep Giga-factories competitive:

- Factory Digitalization - Data Collection & Visualization

- Process Optimization - AI Based Data Analytics & Procedure Enhancement

- Quality Control - Quality Inspection By Deep Learning

- Production Automation - AI controllers of Robot, Cobot, AGV/AMR

Features of Advantech Solutions

The giga-factories and its IEM & SI suppliers are facing global competition. High production capacity, high quality and manufacturing cost down are the keys to winning and keeping market share. Advantech offers comprehensive solutions featuring modular design, cloud connectivity capabilities and advanced computing, communication technologies to support IEMs & SIs to quickly build & connect high efficiency manufacturing and test equipment, helping the giga-factories to quickly ramp up their capacities with best quality and low cost.

Modular Design

Modular design enables IEMs & SIs to build customized systems by using building blocks to quickly fulfil their project demands and reduce system qualification effort.

Cloud Connectivity

Remote management features reduce on-site service costs for OEMs & SIs, and increases capacity utilization for the giga-factory owner. Amazon AWS and Microsoft Azure certified platforms enable machine to cloud connectivity for data analytics, device & software management and AI model edge inference deployment.

AI / Machine Learning

AI/ML enables high speed inspection, precise material handing, predictive maintenance and process optimization to enhance efficiency of giga-factories.

High-Performance Vision Platform

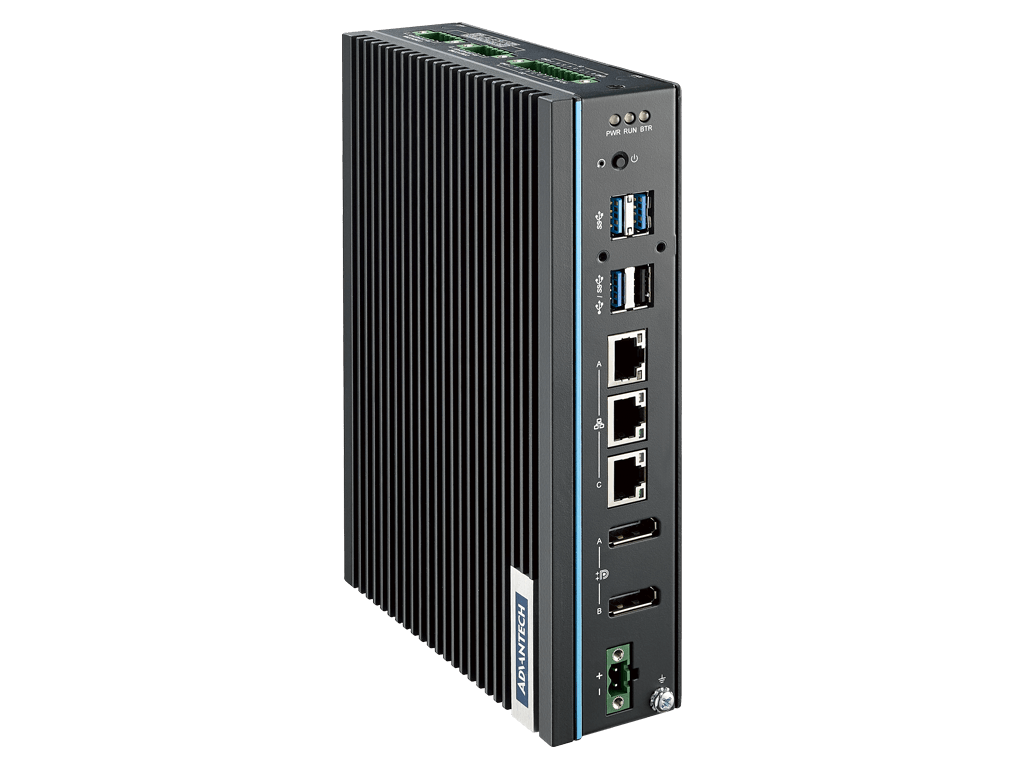

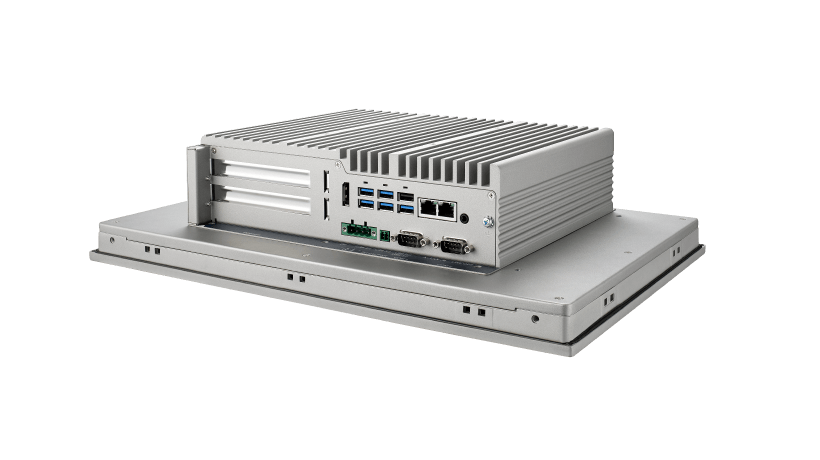

Advantech machine vision solutions consisting of cutting-edge CPU/GPU computing platforms, frame grabbers and smart cameras for IEM/SI can be used in many applications during the production process in order to build state-of-the-art quality inspection and create vision-guided robot/AMR solutions.

Real-Time Control Platform

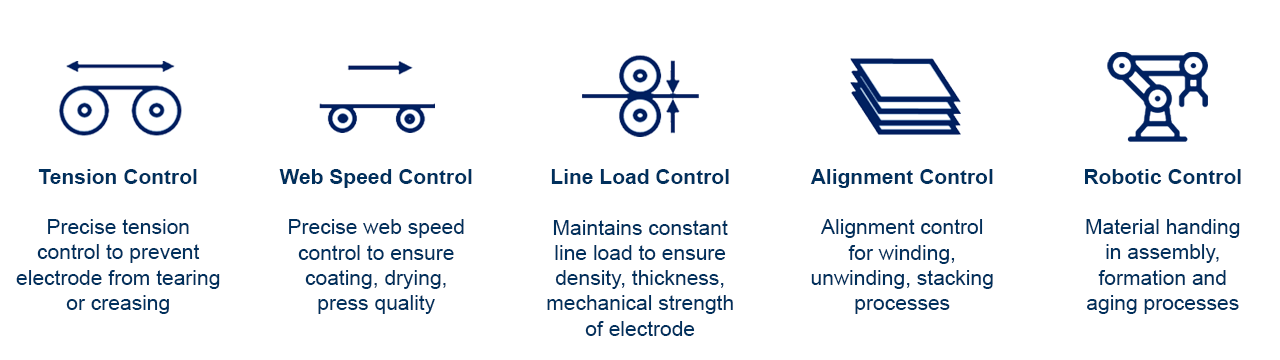

Advantech real-time solutions consisting of compact, rugged platforms, I/O modules and EtherCAT or CODESYS software for IEM/SI can be used to build front-end roll-to-roll electrode and back-end cell/pack assembly equipment for multi-axes, deterministic and low latency control.

Related materials

Technical Article

High-performance vision and real-time control solutions boost

lithium-ion battery manufacture

Ken Lin, Senior Product Sales Manager, Advantech Europe

Green Energy Technology Trends & Solutions Guide

Discover the future of green energy with comprehensive insights into renewable energy trends, innovative battery storage solutions, the intricacies of EV battery production, the expansion of electric vehicle charging stations, and the rise of digital smart substations, all accompanied by in-depth case studies and graphical application diagrams.

Application Shorts

Interview with Ken Lin, Senior Product Sales Manager, Advantech Europe

Hosted by Tim Taberner, Technical Sales Director, Advantech Europe

About Advantech

Advantech’s corporate vision is to enable an intelligent planet. The company is a global leader in the fields of IoT intelligent systems and embedded platforms. To embrace the trends of IoT, big data, and artificial intelligence, Advantech promotes IoT hardware and software solutions with the Edge Intelligence WISE-PaaS core to assist business partners and clients in connecting their industrial chains. Advantech is also working with business partners to co-create business ecosystems that accelerate the goal of industrial intelligence.

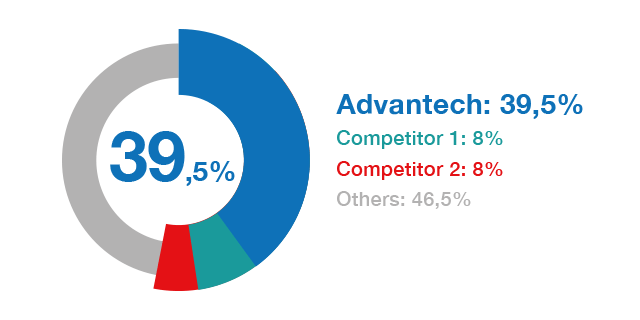

Global #1 Industrial PC Manufacturer

Advantech has a global market share of 39.5% for Industrial PCs.

Source: OMDIA – Market Share estimates for Industrial PCs: World, 2021 Edition

Connect with our Team

Alicja Strzemieczna

IIoT Sales Director,

Central Eastern Europe

Rick de Vries

IIoT Sales Director,

DACH & Benelux

Marco Zampolli

Industrial IoT

Product Sales Director

Ken Lin

Industrial IoT

Product Sales Manager

Daniel Sun

Industrial IoT

Product Sales Manager