Unleash Production Capability For European Lithium Ion Battery Giga-Factories

High speed machine vision for electrode/ cell quality assurance

Real time control for roll-to-roll and assembly manufacture processes

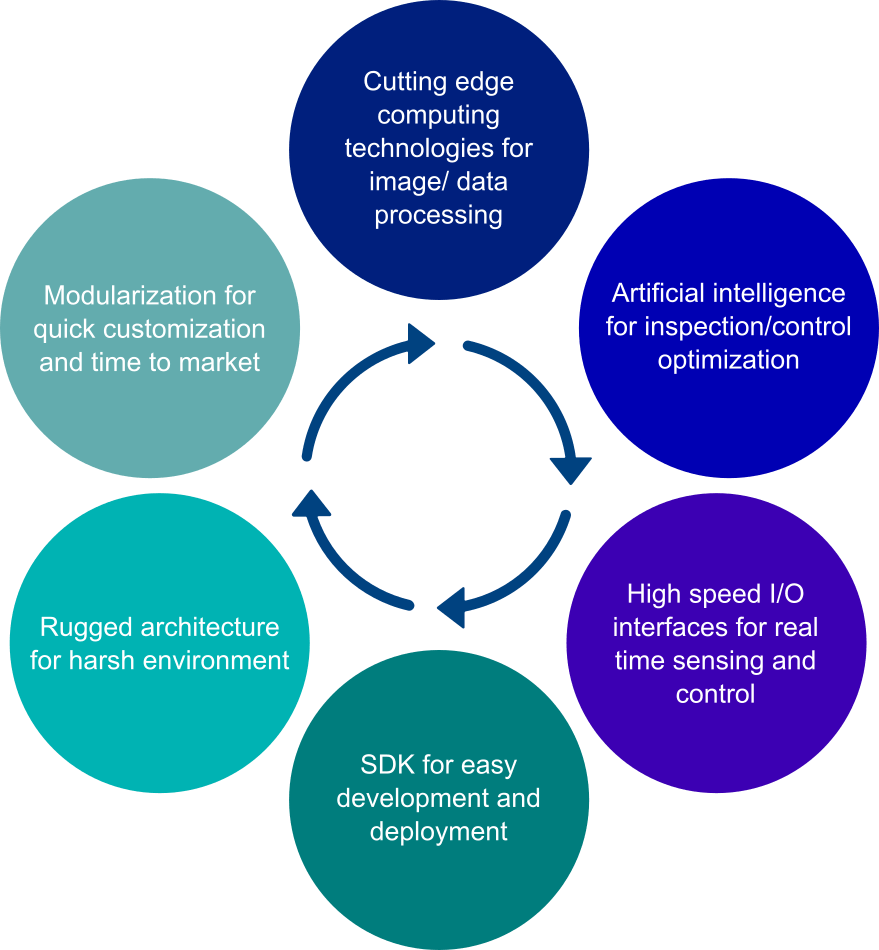

Improve the Operational Performance

Improving operational performance is the most effective way for battery producers to become cost competitive. To achieve operational excellence, battery producers must adopt the concepts of the factory of future, in which Industry 4.0 technologies enhance plant structures and processes.

By transitioning to the factory of the future:

Reduce up to 20% of total battery cell costs per kilowatt-hour (kWh)

The production-related costs (excluding materials) can be reduced by 20% to 35% in each of the major steps of battery cell production:

- electrode production - faster drying times

- cell assembly - data-driven automated adjustment of parameter settings increase accuracy and reduces production times

- cell finishing - shorter times for formation and aging

35%

of the overall electric vehicle cost belong to the battery back.

Car manufacturers that seek to reduce the cost of electric vehicles have a clear vision: reduce the cost of battery packs

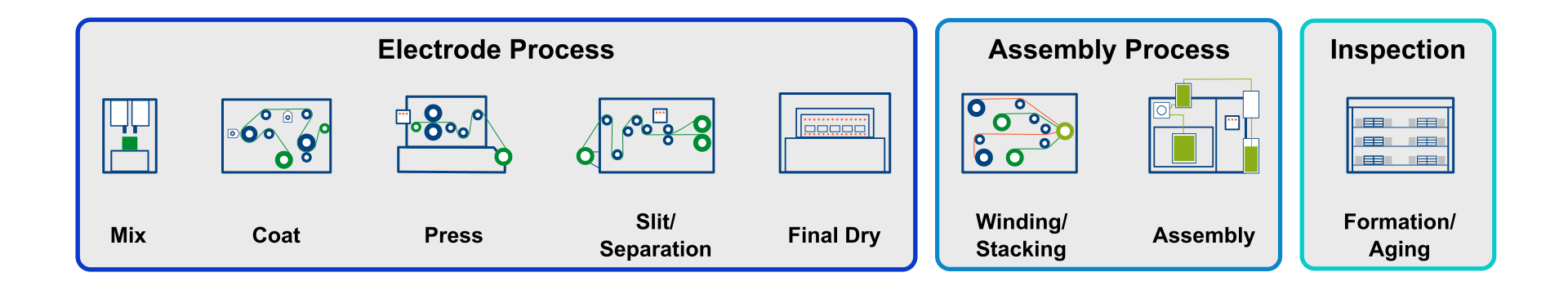

Lithium Battery Cell Production Process

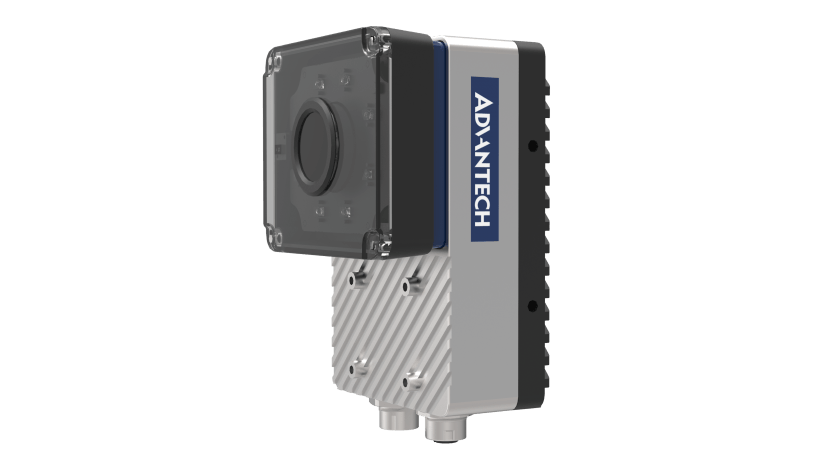

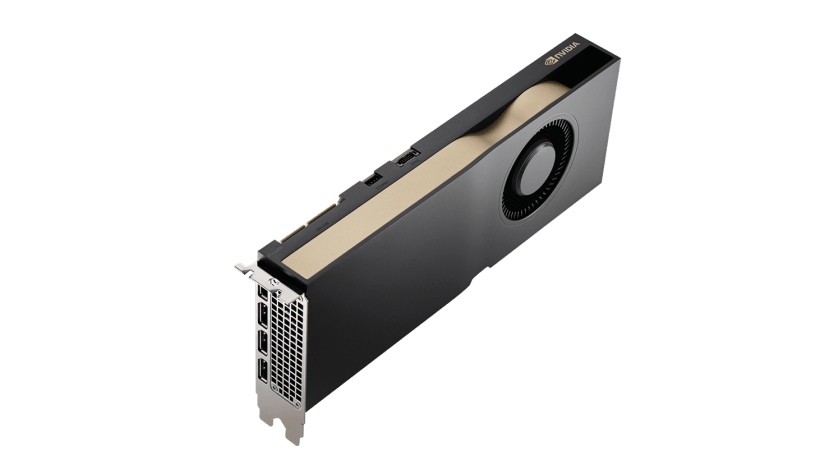

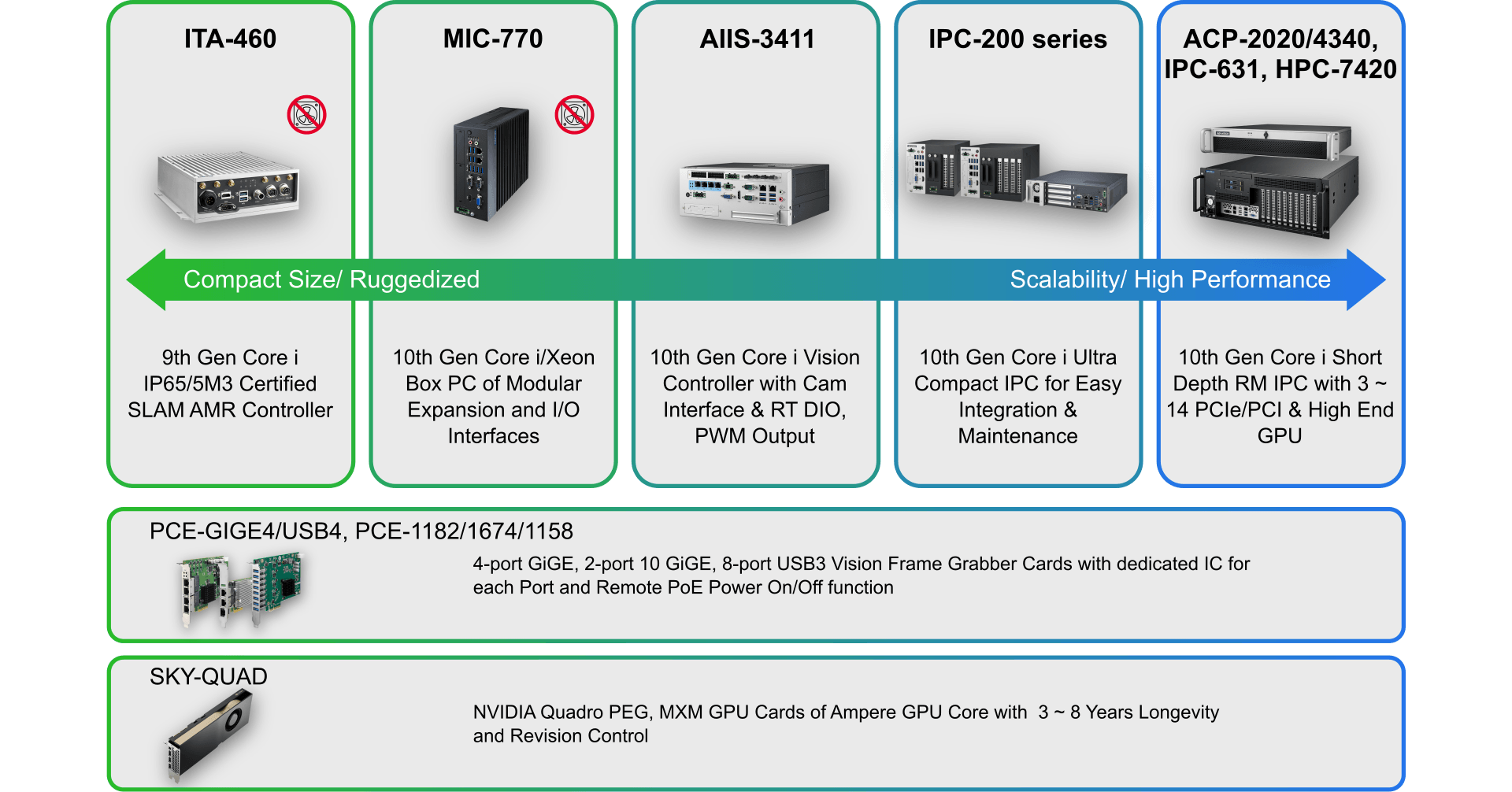

High-Performance Vision Platform

Geometry of coated slurry, cutting edge, surface and outline of silt/punched electrode, alignment of stacked/wound electrode, dimension and outlook of welded shell/pouch all need being accurately inspected, these are where high performance vision systems are used for. Advantech offers platforms of latest CPU/GPU, I/O technologies in different form-factors for machine vision applications.

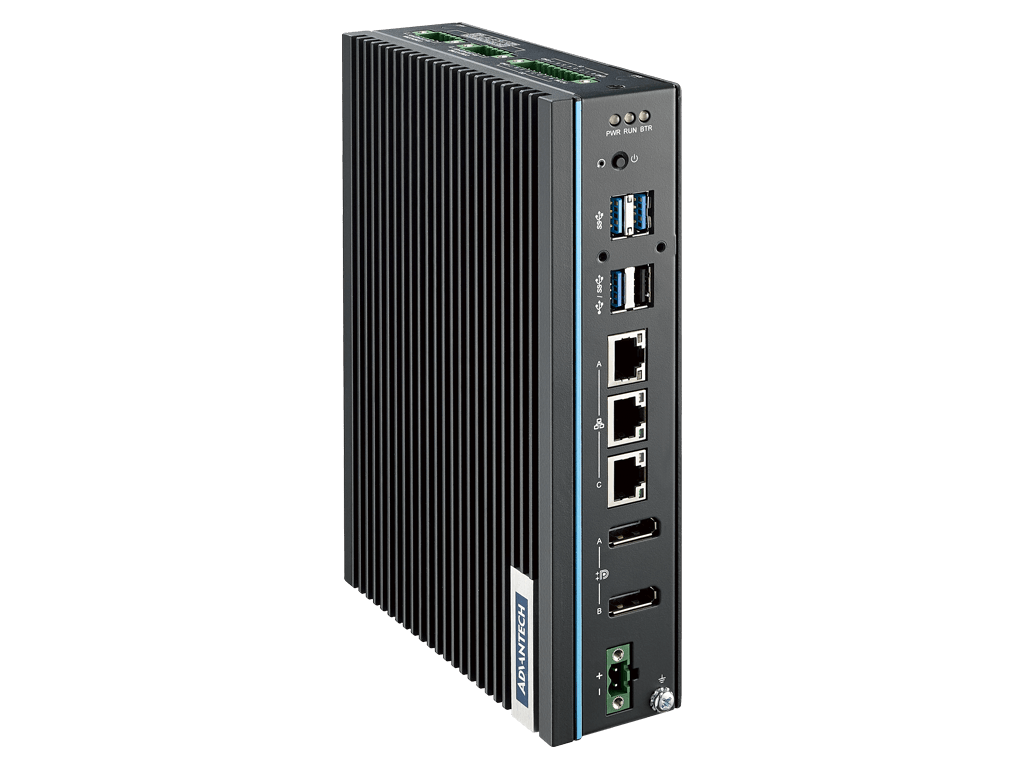

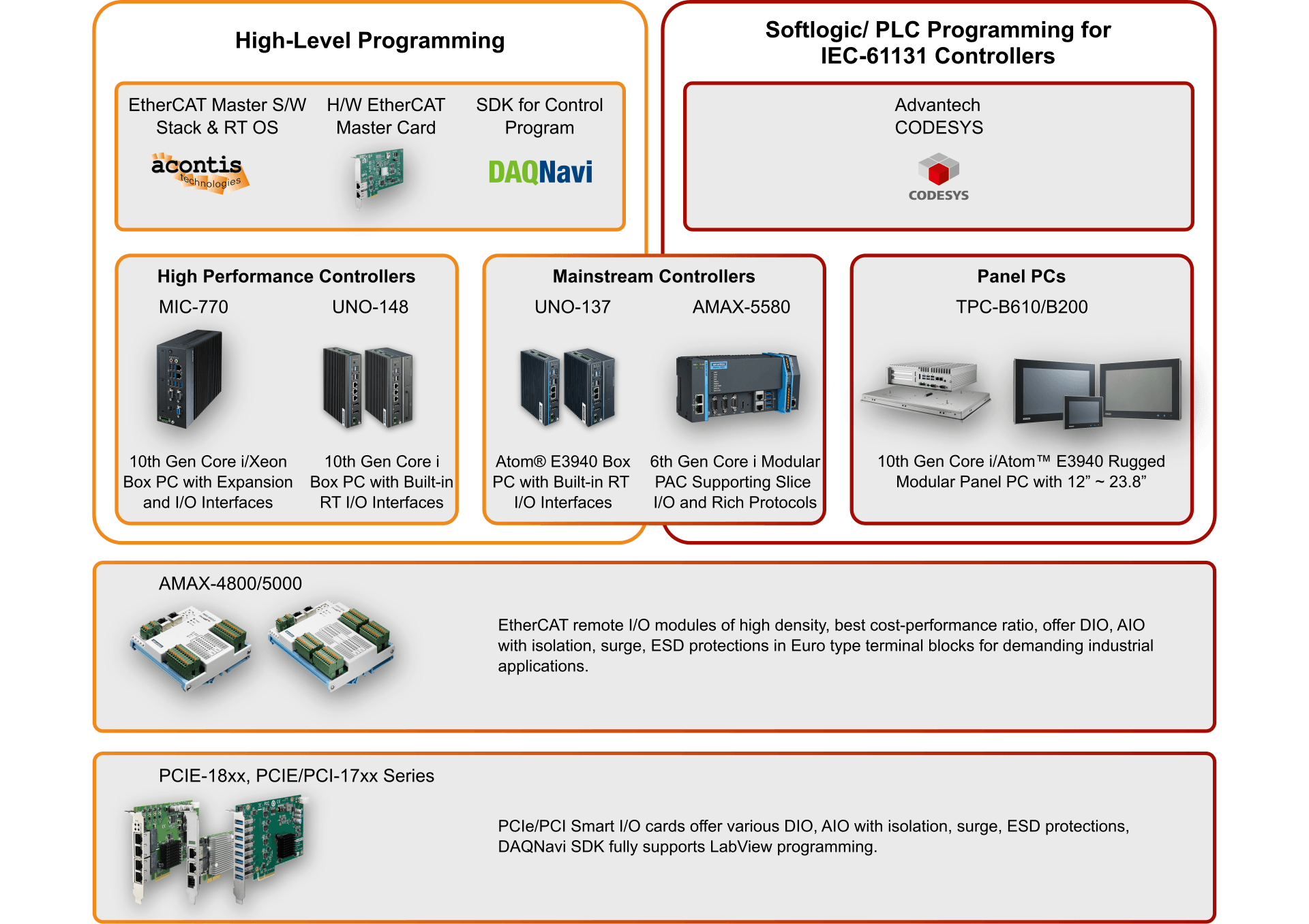

Real-Time Control Platform

In the roll to roll processes, tension, web speed/alignment, roller line-load, space between rollers all need being accurately controlled, in the assembly, formation/aging processes automated material handing is needed for enhancing efficiency and avoiding quality issues. Advantech offers real-time control platforms featuring EtherCAT and IEC 61131 Softlogic technologies.

About Advantech

Advantech’s corporate vision is to enable an intelligent planet. The company is a global leader in the fields of IoT intelligent systems and embedded platforms. To embrace the trends of IoT, big data, and artificial intelligence, Advantech promotes IoT hardware and software solutions with the Edge Intelligence WISE-PaaS core to assist business partners and clients in connecting their industrial chains. Advantech is also working with business partners to co-create business ecosystems that accelerate the goal of industrial intelligence.

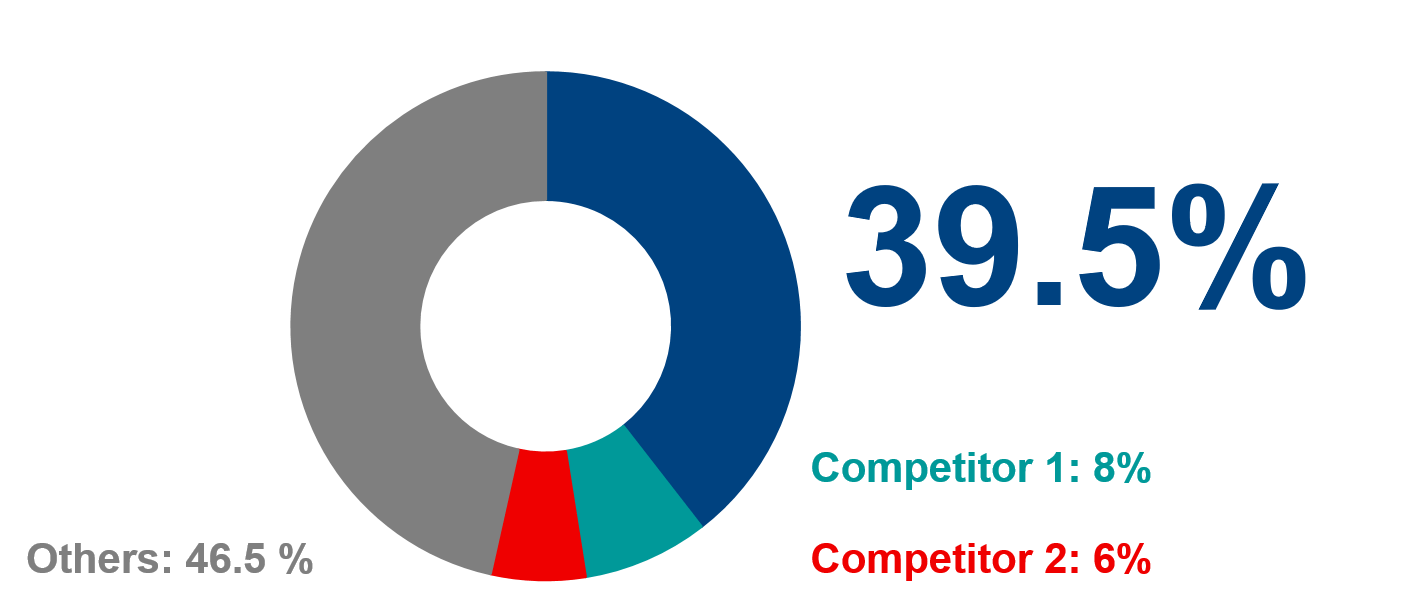

Global #1 Industrial PC Manufacturer

Advantech has a global market share of 39.5% for Industrial PCs.

Source: OMDIA – Market Share estimates for Industrial PCs: World, 2021 Edition